Printing Technologies

Introduction

At Plain-Talk Print, we use a variety of printing

and finishing technologies to balance the need for top quality at affordable

prices. All printing technologies have advantages and

drawbacks. We can give you free, no-obligation advice on how to achieve your

the best results for the quantities you need, within your budget — simply

call our Design Advice Line on 01457 778788.

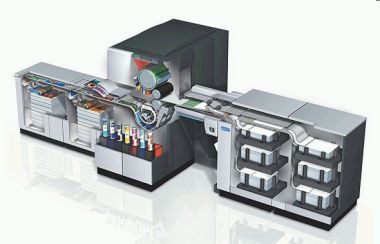

Offset litho printing

By far the most common, offset litho (often

shortened to just 'litho') is extremely cost effective for medium to very

long print runs. The intial expense is in making metal printing plates, but

once these have been created and loaded on to the press, they can produce

one or one million prints. The cost of the paper and ink is relatively very

small.

Ink is applied to the metal plates via series

of rollers and then, via another series of rollers, to the paper. Because

the

plates never actually touch the paper itself the printing operation is referred

to as 'offset'.

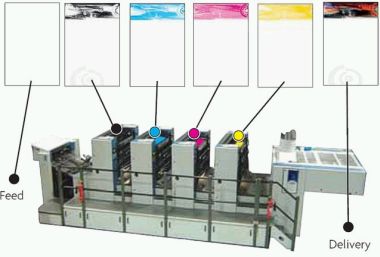

There are two ways of printing using this technique.

The first is process, or CMYK printing. CMYK refers to the four ink colours

used (cyan, magenta, yellow and black, known as in print parlance as key

— hence K).

By using these four colours it is possible

to print almost every colour of the spectrum. It is suitable for the vast

majority of colour printing and since the press is always loaded with these

four colours of inks, it is surprisingly inexpensive.

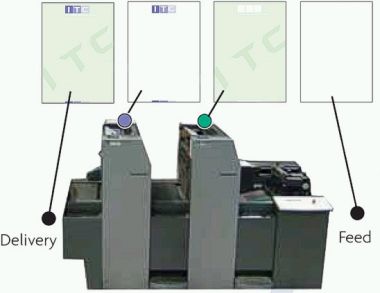

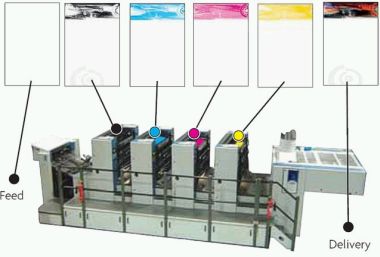

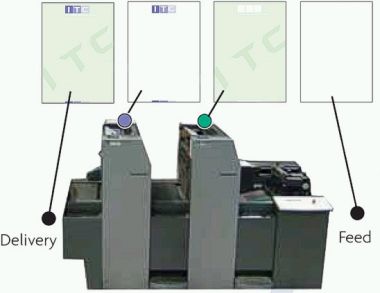

The other common use of offset litho machines

is called spot colour printing. This is used where precise colour matches

are needed.

Here, inks are specially mixed according to

a formula guide (most commonly Pantone®, but other guides exist) and

are loaded into the stations of the press. The diagram above shows a two-colour

letterhead being prepared with precisely-mixed green and purple inks.

Although it may seem strange, full colour process

is often cheaper than spot colour printing. This is because spot colour printing

is more labour-intensive — read more about this in our article

on Spot Colour vs. Full Colour Printing.

Digital printing

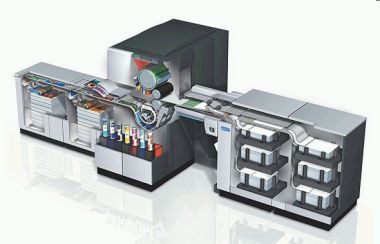

Digital printing covers a multitide of technologies,

but we use it to refer specifically to our Xeikon and HP Indigo digital presses.

Digital presses are very different from domestic

colour laser printers and colour copiers in that they use liquid inks rather

than powdered toners. The resulting prints have the feel of litho prints,

not heat-fused sheets such as those resulting from copiers and printers.

Our Xeikon press can also cope with much heavier stocks than other machines

— up to 350gsm (grams per square metre), whereas most laser printers

would struggle with anything about 160gsm.

Digital presses have the advantage over litho

where only short runs (ie. small quantities) are needed. Since there are

no plates to prepare and load the so-called makeready time is shortened considerably.

For the same reason, the press does not need to produce identical prints

as part of the same job — every print can be different if that is what

is required.

We use digital presses most commonly for

small orders of posters up to A2 in size. For larger posters, we use a different

printing technology entirely, known as large format printing.

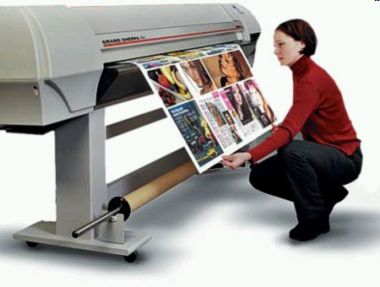

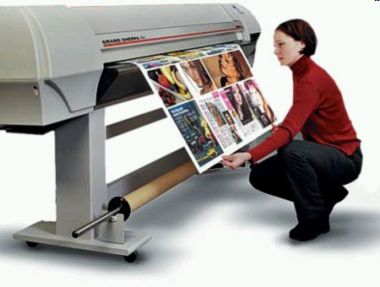

Large format printing

Large format in this context refers to anything

larger than A3 in size. The printers which produce this work are also capable

of printing on an amazing variety of substrates (materials) which can withstand

all kinds of extreme environments.

Large format printers work in a similar way

to domestic inkjet printers but with a much larger platen (print width) and

often up to eight ink colours. This combination of features means that huge

prints can be produced, in our case up to 1,524mm wide, yet with true photographic

quality.

Large format printing is costly and therefore

the inks and materials are developed to last a long time. There are two kinds

of inks: dye-based, for indoor use, and solvent-based, which is resistant

to UV (ultraviolet) light from the sun's rays and therefore suitable for

outdoor use.

Among the many substrates we can print on using

the large format machines are:

- Photorealistic matt paper, suitable for the vast majority

of indoor uses and window displays.

- Wet strength paper, designed for use on billboards and

flat outdoor surfaces.

- Opaque adhesive film, which is used for permanent window

displays.

- Translucent adhesive film, for illuminated displays

such as backlit shop signage.

- Pressure sensitive vinyl, intended for vehicle graphics

but suitable for any permanent outdoor application.

- Banner vinyl, which is usually fitted with brass eyelets

and synthetic rope for affixing to fences and walls.

- Treviera polycloth, a lightweight yet strong fabric

ideal for printed flags.

To protect these prints we offer a variety

of mounting and encapsulation options including films of varying thicknesses

and finishes, depending on the intended use and location of the completed

print.

Because of the huge number of combinations

of sizes, materials and finishing choices we recommend you contact us for

advice on how to get the best solution for your large format printing needs

at the best price possible.

Other print technologies

Although the previous three technologies — offset

litho, digital and large format — cover the vast majority of our work,

there are always situations we need something a little different.

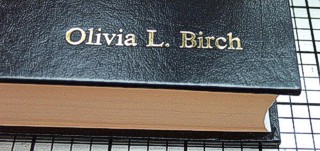

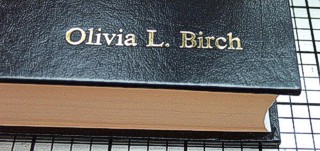

Hot foiling

Hot foiling works by pressing a specially made,

heated metal die against a coloured foil and the product to be printed. Where

the hot die meets the foil, it melts and is permanently bonded to the surface.

Although commonly used for books, as shown

above, it can be used on a variety of papers and cards (especially our card

badges) to great effect, but as might be expected from a process requiring

the manufacture of a metal

die, it is rather costly. Once the initial cost of the die has been met,

however, it can be used for subsequent print runs at a much lower cost.

Forcejet®

Our Forcejet inkjet printer is used for

overprinting lightweight paper items. The print quality is suited to adding

detail such as seat numbers to theatre tickets or addresses to mailpieces

and the machine processes these items very quickly.

Crash numbering

Used exclusively for NCR (no carbon required)

forms, crash numbering involves striking the topmost form of a set with metal

numerals on inked rotating wheels. The impact causes the number to appear

on all of the sheets in the set. The wheels rotate as the next set is moved

into position so that all the sets are numbered uniquely.

Questions

If you have any questions about anything in

this article, please feel free to contact us using our

Design Advice Line on 01457 778788 for plain-English

advice with no obligation whatsoever.

.